General characteristics of the MSK2-90 sewage pump

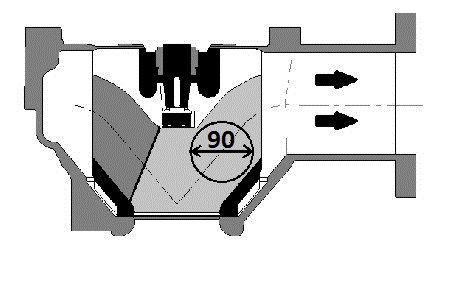

MSK2-90 sewage pumps are intended for pumping sanitary and industrial sewage as well as drainage and rainwater. They are used in sewage systems, sewage treatment plants and pumping stations as well as all types of drainage systems. MSK2-90 are also excellent pumps for recirculation of sludge and process water in sewage treatment plants. Free passage through the impeller channel of solids up to 90mm in size ensures trouble-free operation with pipelines with cross sections Dn200, Dn250 and larger. The pumps have a temperature limiter in three phases of the motor stator windings and a humidity switch. These elements exclude the possibility of damage to the engine in the event of overloading or moisture ingress. The motor is sealed from the pump unit side with a double mechanical seal. The pump is equipped with a 10 m long neoprene sheath cable.

Working conditions of raw sewage pumps MSK2-90

Sewage density up to 1100kg / m³

Fluid temperature up to 40 ° C

Maximum number of starts up to 20 / h

Submersible pumps MSK2-90 |

Channel

|

Passage |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mechanically treated sanitary sewage, industrial and rainwater |

|||||||||||||

| No. | Pump | Power [kW] | n [rpm] | Qn [l/s] | Hn [m] | In1 [A] | ZPS2 [A] | cos φ | η [%] | Passage [mm] | Auto coupling | Weight3 [kg] | Price4 |

| 1 | 18 | 1,1 | 705 | 19,0 | 2,9 | 3,4 | 4-6,3 | 0,65 | 72 | 90 | KS100 | 112 | 10 900 |

| 2 | 26 | 2,2 | 925 | 22,0 | 4,8 | 5,4 | 4-6,3 | 0,78 | 75 | 90 | KS100 | 114 | 11 400 |

| 3 | 44 | 4,0 | 1415 | 26,0 | 7,2 | 9,2 | 10-16 | 0,78 | 81 | 90 | KS100 | 116 | 12 000 |

| 4 | 124 | 12,5 | 1455 | 74,0 | 7,2 | 24,1 | 32 | 0,89 | 89 | 90 | KS150L | 267 | 27 600 |

| 5 | 154 | 15,0 | 1460 | 76,0 | 8,6 | 27,7 | 32 | 0,87 | 89 | 90 | KS150L | 282 | 31 900 |

| 6 | 184 | 18,5 | 1455 | 82,0 | 11,0 | 35,1 | 40 | 0,85 | 89 | 90 | KS150L | 302 | 36 100 |

| 7 | 224 | 22,0 | 1455 | 87,0 | 13,0 | 43,2 | 63 | 0,92 | 92 | 90 | KS150L | 317 | 40 200 |

- For pumps to 4,0kW start directly for other Intermediate star-delta starting.

- Motor overload protection.

- Including 25kg ZP150 or 7kg ZP80-ZP100 pump hitch and 10m cable.

- The prices in PLN are net prices and do not include transport costs to the customer.

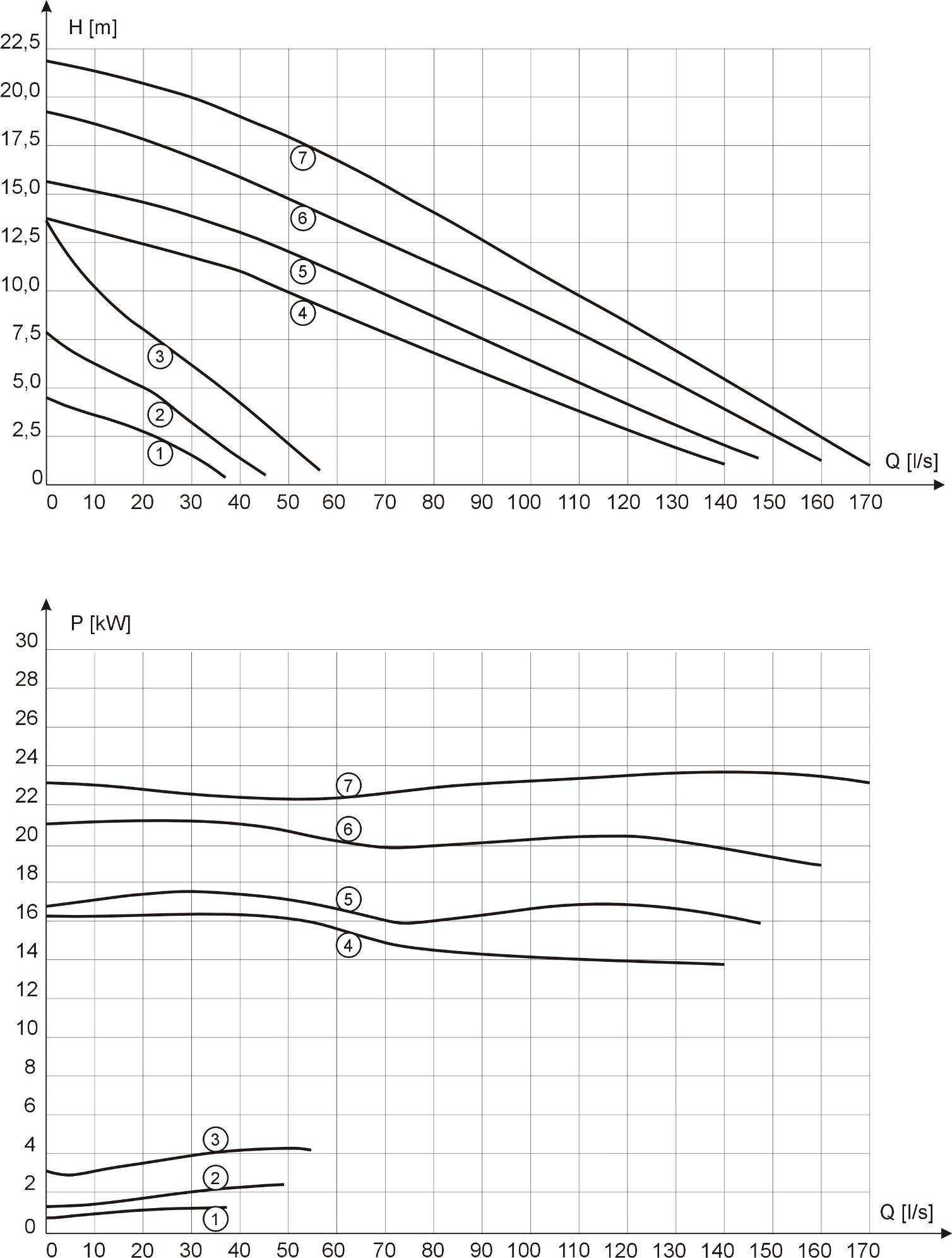

Characteristics of MSK2-90 sewage pumps

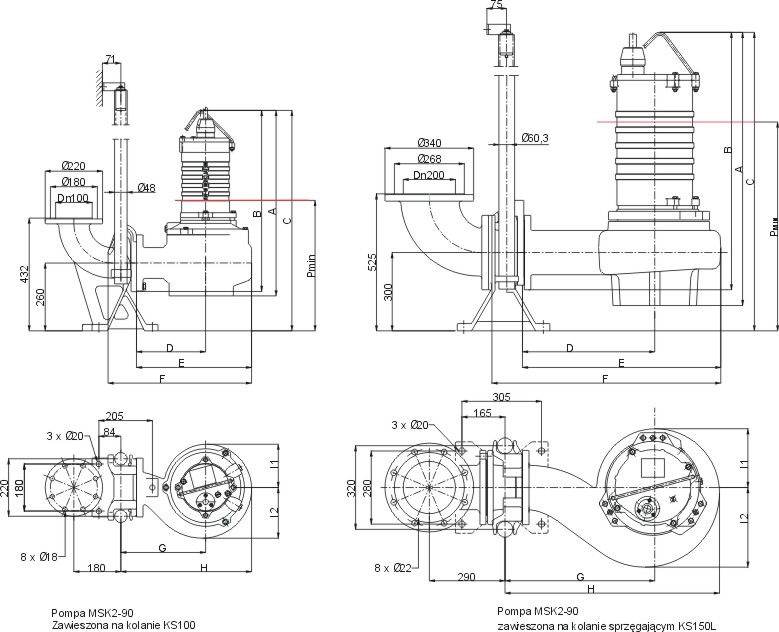

Drawings and dimensions of sewage pumps MSK2-90

| No. | Pump | A | B | CKS150M | D | E | FKS150M | GKS150M | HKS150M | I1 | I2 | PMIN |

| 1 | 124 | 1024 | 954 | 1130 | 375 | 560 | 712 | 442 | 662 | 220 | 220 | 800 |

| 2 | 154 | 1024 | 954 | 1130 | 375 | 560 | 712 | 442 | 662 | 220 | 220 | 800 |

| 3 | 184 | 1024 | 954 | 1130 | 375 | 560 | 712 | 442 | 662 | 220 | 220 | 800 |

| 4 | 224 | 1024 | 954 | 1130 | 375 | 560 | 712 | 442 | 662 | 220 | 220 | 800 |

Materials used in MSK2-90 pumps

- Motor body, pump body, impeller, coupling, coupling elbow – cast iron ŻL200, ŻL250,

- Pump shaft – stainless steel,

- Fasteners – stainless steel,

- Bearings – single row ball, double row angular contact ball,

- Double mechanical face seal,

- Epoxy varnish coating

Pump motors 400V/50Hz

Insulation class F

Compliance with standards

ISO 9908

ISO STANDARD 2548 CLASS B

Download